Surprising Preliminary? Amazing!

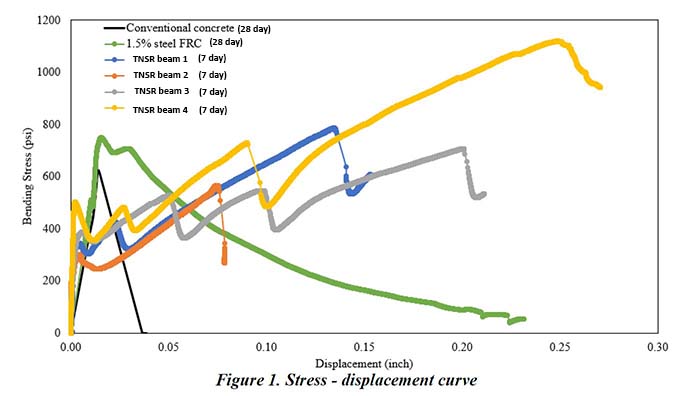

It is rare in the extreme that initial testing on some material exceeds the wildest expectations, especially if it is a garage development. In this case, these test beams exceeded the research lab’s ability to detect deflection…their ruler was too short! That green line is a typical fiber reinforced concrete (FRC) graph per ASTM 1609. We say it represents 60 years of structural engineering success…and TNSR Swole-Crete is throwing shade!

An interesting feature of these lab results is that the test beams were unable to recreate the actual geometry of how the patented tool operates.

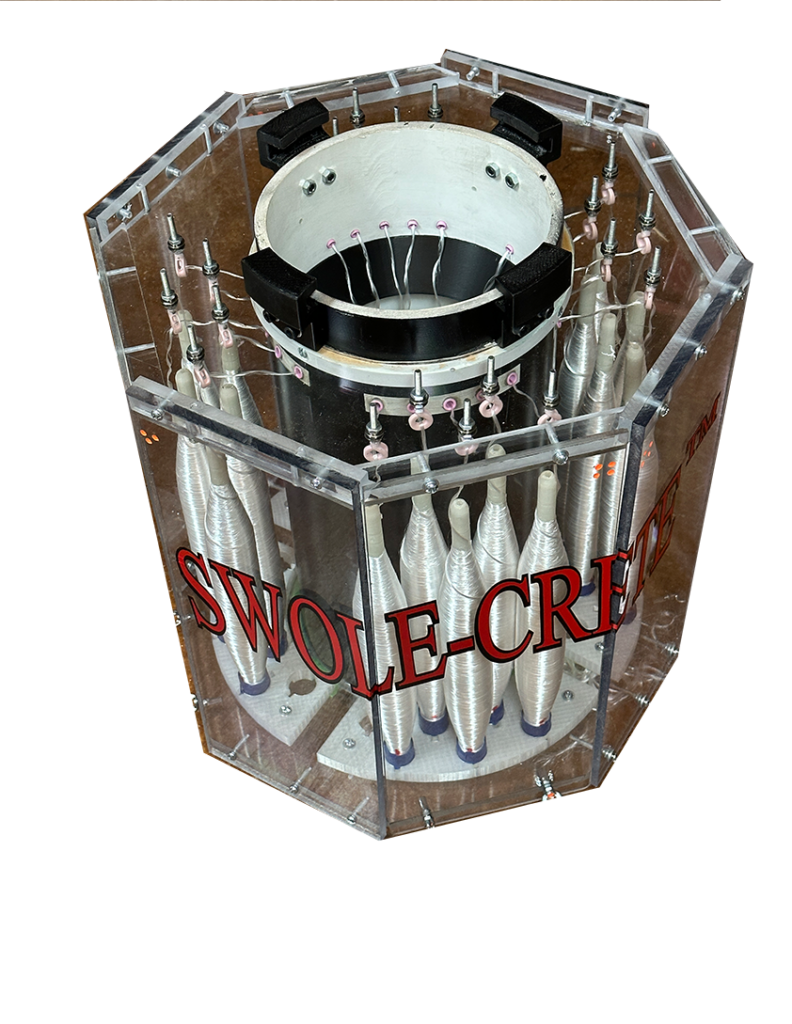

Fiber Distribution Ring

Each bobbin of Ultra-High Molecular Weight PolyEthylene (UHMWPE) fiber in the TNSR Fiber Distribution Ring holds at least 1800 feet of fiber. Depending on delivery RPM, the amount of high strength UHMWPE fiber delivered might increase the cost of concrete $25 per cubic yard while at the same time increasing flexural strength and durability more than forty (40) percent. All of this being accomplished without changing the concrete supply chain or mix recipes in any way. It also has the capability of handling multiple types of streamable substances at the same time on differing bobbin sizes. Swole-crete!

Admire UHMWPE Strength!

Success on the first attempt was not expected by “experts”.

• Reviewing leading textbooks, like “Reinforced Concrete: Mechanics…” by James Wight, and thirty years of engineering reports informs you that one cannot significantly increase the tensile strength of concrete by adding fibers. In fact, interesting tests for Fiber Reinforced Concrete (FRC) like ASTM 1609 are not as commonly performed today because of this general understanding.

• The TNSR Delivery Mechanism continuously streams Ultra High Molecular Weight Polyethylene (UHMWPE) fibers, today’s strongest production fiber. FRC applications to this point have always used chopped fibers (~2″) added into the concrete mixer.

Would rebar add tensile strength to concrete if it were chopped into 2″ pieces?